What do you know about ball screws versus ACME screws? Both of these types of screws are popular. They convert circular motion to linear motion when the screw is turned and the nut is fixed in place or the nut is turned and the screw is fixed in place.

Ball screws don’t have much frictional loss so they experience less physical wear and tear than other screws. With ball screws you’ve got a screw and a nut with balls rolling between matching helical grooves. When the screw or nut is rotated, the balls get deflected into the ball return system of the next, traveling through the return system to the opposite end in a continuous path. This is an efficient system allowing for a high force, speed and duty cycle. One note though: ball screws can back drive because they have low internal friction and this could be a safety concern.

The Advantages of ACME Screws

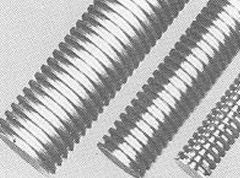

ACME screws are common because they are easy to manufacture, offer high strength and work well where large loads are required. They use trapezoidal threads to roll onto the lead screw. Threads can push the shaft nut forward or backward as the circular force transfers into linear motion on the shaft. ACME screws work well for most industrial applications. They are known to be quiet, efficient and strong.

What kind of screws do you want or need for your application(s)? You can call Dependable ACME and discuss your needs. The number is 800-893-3792. You can also email depacme@aol.com. Dependable ACME has been in business for many decades and is a great source for quality ACME threaded products, including screws, nuts and rods. Specifically, Dependable ACME sells screw threads from ⅜” to 2.5” diameter.